پیشینه فعالیت مدیران شرکت به چندین دهه قبل باز می گردد آنجا که بزرگ خاندان حاج حسن مکاریان در آن سال ها فعالیت های مختلفی در زمینه موتورسیکلت و قطعات داشته اند که می توان به دریافت نمایندگی سوزوکی در سال ۱۳۴۲ در استان خوزستان اشاره کرد.

رضا مکاریان که از نوجوانی در کنار پدر به کسب تجربه پرداخته بود و پس از آن نیز سالها در این کسب و کار خانوادگی فعالیت داشت در سال ۱۳۸۰ تصمیم به تاسیس شرکت شاهین موتور در شهرک صنعتی شکوهیه قم گرفت .

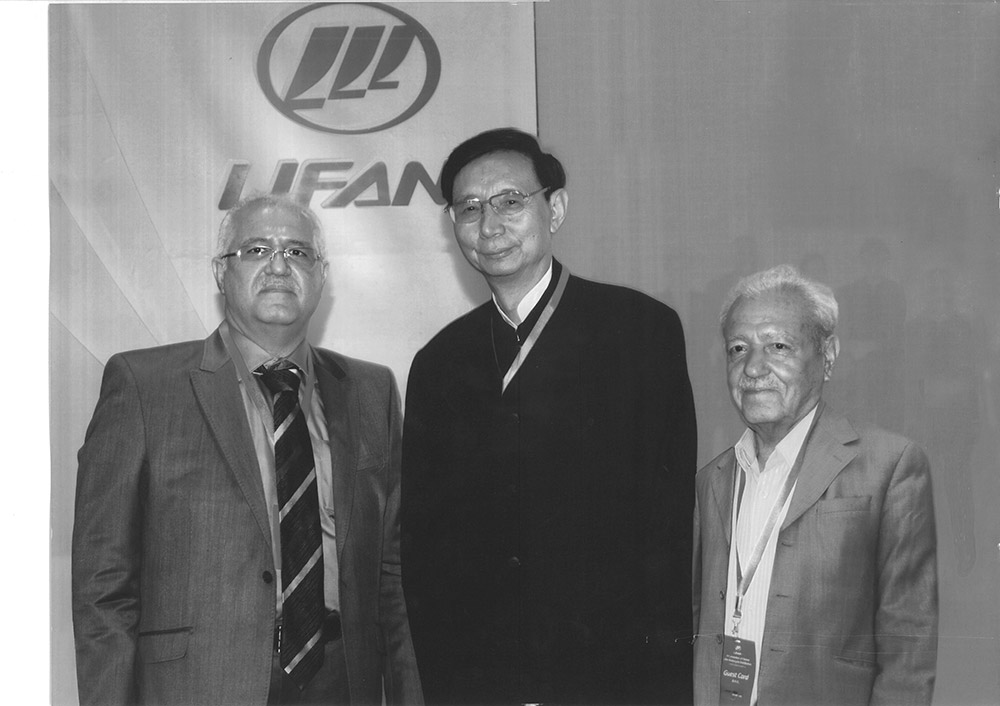

در ابتدا فعالیت کارخانه با تولید موتورسیکلت با برندهای دلتا و امجد در حجم های ۱۲۵ سی سی الی ۲۵۰ سی سی آغاز گشت . پس از مدتی با توجه به نیاز بازار با تولید موتورسیکلت با برند های هاتف و آلتون به راه خود ادامه داد .پس از ۱۰ سال فعالیت موفق و همکاری مستمر با شرکت لیفان در سال ۱۳۹۰ شرکت لیفان شاهین موتور را به عنوان نماینده رسمی برند خود در ایران انتخاب نمود . با دریافت نمایندگی رسمی از این شرکت ، خط تولید جدید با برند لیفان در کلاسهای متنوع ایجاد گردید که قدم به عرصه ای نو در تولید موتور سیکلت هایی با کیفیت برتر گذاشت.

از آنجا که حفظ و ارتقاء کیفیت و ایمنی محصولات تولیدی یکی از اصلی ترین اهداف کارخانه شاهین موتور می باشد. به منظور نیل به این هدف، خط تولید جدید مجهز به کانوایر تغذیه خط تمام اتوماتیک و به روز با ماشین آلات مربوطه ، میزهای پیش مونتاژ و دستگاه شماره زن با قابلیت RFID چیپ توسط مهندسان مجرب شرکت لیفان نصب و راه اندازی گردید .

دستگاه تست پایان خط شامل سنجش آلایندگی ،ماکسیمم سرعت ،شتاب اولیه ،شتاب ثانویه ،ترمزهای جلو و عقب، همراستایی ،صدا و نور میباشد . همچنین بمنظور اطمینان از حفظ کیفیت محصولات در زمان تولید ، کلیه محصولات تولید شده پس از انجام تستهای فوق طبق نمونه شاهد کنترل و پس از تائید کارشناسان کنترل کیفیت جهت کاور به انبار منتقل میگردد .

بخش آزمایشگاه مجهز به دستگاه های سالت اسپری،فیکسچر شاسی و انجین ، تست رنگ ، تست جوش اگزوز و خراش انداز میباشد .تمامی اقلام ورودی شامل مواد اولیه و مصرفی حین فرآیند تولید در آزمایشگاه کنترل کیفیت با بهره گیری از تجهیزات آزمایشگاهی ذکر شده مورد آزمون واقع می شوند.

به منظور استفاده بهینه از فضا، سیستم انبارش در ارتفاع مورد استفاده قرار گرفته است که بدین جهت انبار طبقاتی محصول با ارتفاع ۱۲ متر در ۴ طبقه در نظر گرفته شده است.

ساختمان اداری کارخانه شامل واحد مدیریت کارخانه ،کنترل کیفیت ، شماره گذاری موتورسیکلتها ، سالن کنفرانس ،سالن اجتماعات و سوئیتهای اقامتی میهمانان بصورت مستقل از فضای تولید در حال استفاده میباشد .

پس از آنکه محصول تحویل مصرف کننده می شود، واحد خدمات پس از فروش وظیفه ارائه خدمات فنی و غیره را به کلیه محصولات در حوزه گارانتی در سراسر کشور را به نحوه مطلوب و با کیفیت مناسب به طوریکه رضایت مشتری حاصل شود را عهده دار است.

واحد خدمات پس از فروش شرکت شاهین موتور در ساختمان جدیدی با مساحت تقریبی ۲۲۰ متر مربع در دو طبقه در راستای اهداف شرکت در حال احداث و راهاندازی میباشد . هر دو طبقه این ساختمان به خدماتی مانند سرویس های اولیه ،عیب یابی ،تعمیر و تأمین قطعات اختصاص یافته است و واحدهایی از جمله امور نمایندگان و رضایتمندی مشتری را شامل میشود.

دفتر مرکزی شرکت شاهین موتور واقع در تهران در فضایی به مساحت ۵۰۰ مترمربع در چهارطبقه شامل واحد های مدیریتی مجموعه می باشد.

ویدئو تور مجازی

در طی چند سال اخیر با توجه به برنامه ها ی دولت در خصوص کاهش مصرف بنزین و طرح جامع مبارزه با آلودگی هوا، اقدامات اساسی در ارتباط با تولید و مونتاژ موتورسیکلت های انژکتوری صورت گرفت بطوری که کلیه موتور سیکلتهای این شرکت با انجین انژکتوری یورو ۴ (EURO 4 ) تولید میگردد و همچنین در راستای توسعه حمل و نقل پاک و کمک به کاهش منابع تولید کننده آلاینده هوا تولید و عرضه موتورسیکلت های برقی در اولویت برنامه های این شرکت تولیدی قرار گرفته است و چندین مدل موتورسیکلت برقی و اسکوتر نیز به محصولات شرکت اضافه و به بازار عرضه گردیده است . .تمامی محصولات تولیدی این شرکت دارای تائیدیه سازمان ملی استاندارد ایران میباشد. از دیگر افتخارات این گروه صنعتی اخذ گواهینامه سیستم مدیریت کیفیت ایزو ۹۰۰۱:۲۰۰۸ از شرکت JAS-ANZاسترالیا و ارتقا آن به ورژن ۹۰۰۱:۲۰۱۵ توسط شرکت الیانس در راستای رشد کمی و کیفی خدمات رسانی و مشتری مداری میباشد.

شرکت شاهین موتور در طول فعالیت خود همواره در تلاش برای جلب رضایت مشتریان، افزایش میزان رضایت مندی آنها با افزایش کیفیت محصول و ارائه خدمات پس از فروش مطلوب به کلیه مصرف کنندگان بوده است.

مدیران و پرسنل شرکت در تلاش هستند با بهره گیری از حداکثر توان علمی- فنی و دانش محور خود و با به کارگیری مدرن ترین تکنولوژی و ماشین آلات، در راستای اختصاص جایگاهی مستحکم تر در این صنعت گام بردارند. نتیجه این فعالیت ها و تلاشها تا کنون باعث گردیده که شرکت شاهین موتور بعنوان یکی از ده شرکت برتر تولید موتورسیکلت در ایران شناخته شود.